How to Build a Simple, Scalable Supplier Onboarding Process

Supplier onboarding is one of the most overlooked and underestimated stages of the procurement process. On the surface, it seems straightforward: collect some forms, input a few details, and move on. But in practice, it’s often the first point of friction.

A vendor can’t get paid because accounts payable is waiting on tax documents, legal hasn’t reviewed the contract, and without AP automation, the process takes forever. A new vendor gets manually keyed in again because no one realized they were already in the system. These aren’t rare edge cases. They’re signs of a process that’s unclear, inconsistent, or too reliant on manual steps.

The reality is, supplier onboarding is more than paperwork; it’s the foundation for vendor management, supplier optimization, and long-term procurement success.

And when the onboarding process breaks down, the impact doesn’t stop there. Delays ripple across the organization, including finance and operations. Yet despite the risk, onboarding is rarely a priority—until something breaks.

This article is here to help change that. We’ll unpack what supplier onboarding really involves, where it tends to stall, and how to build a process that’s simple, scalable, and built to last.

What is supplier onboarding?

Supplier onboarding is the structured process of integrating new vendors into your organization’s procurement and operational systems. While it may seem like a matter of collecting forms and entering information, it’s much more than that. Onboarding involves verifying tax details, banking information, certifications, and compliance documents, while also aligning both parties on expectations, responsibilities, and workflows.

The purpose of supplier onboarding is to create a strong foundation for the relationship. It helps minimize risk, ensures smooth transactions, and supports long-term collaboration. When done well, onboarding streamlines procurement activities, significantly reduces the administrative burden, and sets suppliers up for success from the beginning.

Where onboarding breaks down and what to do instead

A well-designed onboarding process does more than make procurement easier. It creates positive downstream effects across finance, legal, operations, and compliance teams.

Thorough onboarding helps identify potential vendor risks early, whether it’s financial instability, lack of insurance, or gaps in regulatory compliance. Addressing these issues before a purchase order is issued protects the organization from costly disruptions or reputational damage. A standardized process also improves purchasing efficiency by reducing delays, eliminating redundant communication, and helping suppliers become active faster without ongoing manual intervention.

Supplier onboarding often breaks down in the same familiar places: collecting incomplete data, managing compliance manually, and relying on email threads to keep everyone aligned. These issues aren’t new, but they’re still surprisingly common.

One of the most persistent friction points is data collection. Without a standard intake process, teams waste time going back and forth with suppliers. Manual entry also introduces errors that slow down approvals and delay payments. Moving to a centralized procurement solution can eliminate much of this noise, reduce errors, and give everyone better visibility.This is also where strong vendor procurement practices come into play, ensuring every new supplier is integrated consistently and accurately, while setting the stage for long-term efficiency.

Compliance continues to be another common sticking point. Building basic compliance checks into your onboarding flow (and making them mandatory) reduces that risk without adding friction.

Communication is the third major pain point. Without a shared workflow or clear accountability, onboarding can stall. Suppliers don’t know where to upload documents, AP doesn’t know who’s approved, and internal teams end up duplicating work. A standardized process, supported by automation and clear roles, helps keep things moving without constant follow-up.

The solution isn’t a massive system overhaul — it’s clarity. A good onboarding process is standardized, documented, and designed to be easy for suppliers to follow. The steps themselves don’t have to be complicated. What matters is that everyone, on your team and theirs, knows what comes next.

What you should know before you start

If you’re revamping your supplier onboarding process or building one from scratch, a few key questions tend to come up. Here’s what to expect — and how to prepare:

Expect five core steps

Most onboarding processes follow a predictable path: discovery and qualification, documentation and contracts, compliance checks, system integration, and a kickoff. The sequence may shift slightly, but the core building blocks stay the same.

Timelines vary

Depending on how complex your requirements are and how responsive your supplier is, onboarding might take a few days or stretch into weeks. The more structured your process, the faster you can move.

You’ll need the right documentation

At minimum, expect to collect W-9s (or equivalents), business licenses, insurance certificates, banking info, and signed agreements. Regulated industries may also require HIPAA, ISO, or other compliance documentation.

Yes, onboarding can (and should) be automated

Supplier portals, intake forms, and risk management tools can all reduce manual work, speed up approvals, and keep everything trackable in one place. Start with automation where it hurts most — usually document collection or compliance. Consider integrations like PunchOut catalogs that streamline supplier relationships post-onboarding, giving teams a direct link between onboarding, purchasing, and ongoing vendor management.

“Supplier” vs. “Vendor”

Both terms are used interchangeably. “Supplier” usually refers to businesses providing goods. “Vendor” is often broader and includes service providers. While the process is mostly the same, internal teams sometimes treat them differently depending on the risk level.

How supplier onboarding priorities shift across industries

Supplier onboarding follows a similar structure across most organizations, but the priorities, risks, and requirements often look very different depending on the industry.

Manufacturing

Speed and precision take priority. A delay in onboarding the right supplier can stall production or impact quality. Manufacturers typically focus on things like ISO certifications, delivery reliability, and seamless integration with inventory or ERP systems. These are non-negotiables when supplier performance directly impacts output.

Healthcare

Compliance drives everything. Healthcare organizations operate under intense regulatory scrutiny — HIPAA, FDA, ISO, and more. That means onboarding must verify credentials, capture documentation securely, and build a clear audit trail. A single missed requirement can lead to serious risk.

Nonprofits

For nonprofits, transparency and cost control matter most. Onboarding processes often include budget tracking by funding source, vendor ethics reviews, and conflict-of-interest checks. The goal is to ensure every dollar spent aligns with donor intent and organizational mission.

Understanding how your industry shapes supplier expectations helps you prioritize what matters most — and avoid unnecessary friction from the start.

What it all comes down to

Supplier onboarding doesn’t need to be a heavy lift, but it does need to be deliberate. The goal isn’t to build a perfect process. It’s to build one that works consistently, even when your team is moving fast or stretched thin.

Whether you’re starting from scratch or cleaning up a legacy workflow, small improvements go a long way. Clarify the steps. Assign ownership. Make it easy for suppliers to get through the process — and easy for your team to manage what comes next.

Good onboarding is invisible. No bottlenecks. No drama. Just a supplier that’s ready to work — and a procurement team set up for long-term success. If you’re ready to take the next step, explore how a vendor management system can centralize onboarding and simplify supplier management at scale.

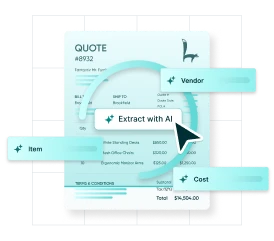

Preview AI Intake for Orders

Take the product tour to see how the new intake experience works.