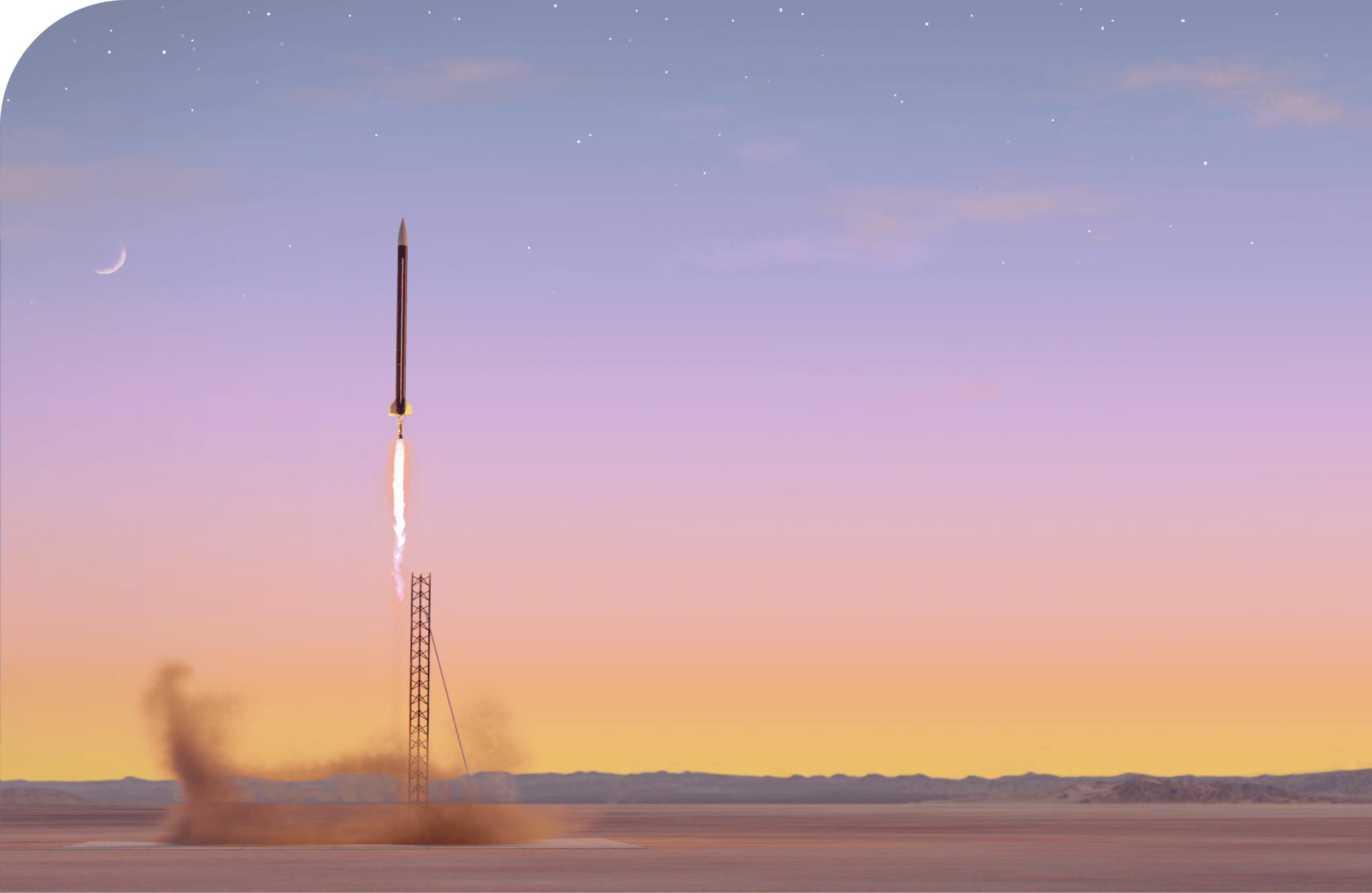

Texas Rocket Engineering Lab (TREL) is an interdisciplinary research lab incubating the next generation of innovators and rocketeers. Located within the University of Texas at Austin’s Cockrell School of Engineering, the team at TREL is in the early development stage of sending a rocket into space, aiming to reach their target apogee of 100km. Partnered with organizations including Firefly Aerospace, Boeing, Amazon Web Services, and Procurify, the team at TREL hopes to continue their research and development to make space exploration accessible to everyone.

TREL does more than build rockets. They inspire students in science, technology, engineering, and math (STEM) to create, test, design, and innovate while driving home the mindset that anyone can have a career in the space industry. Building something as complex as their Halcyon rocket – a liquid bi-propellant rocket – their team of engineers, business managers, and operations managers handle everything from investor relations to building and designing the rocket itself. With US$1 million in funding to report on and launch deadlines to hit, the team at TREL needed a world-class operations system to safely put a rocket into space.

The challenges

Getting a rocket into space takes a team of highly-specialized individuals across a variety of departments, all communicating succinctly. In this type of innovative environment, it is crucial that team members focus on specialized tasks. Bryce Blackwell, Director of Business Operations at TREL, knows that the success of this launch is dependent on his ability to provide the engineers with the materials they need as quickly as possible, without exceeding their financial commitments to their investors and partners.

As additional funding came in and the team continued to grow, Blackwell knew their reliance on Excel and in-person purchasing meetings was no longer scalable, and they needed a system that would act as a central source of truth. TREL’s processes needed to be agile, and they needed to make decisions quickly without jeopardizing the safety of the rocket.

-

Reliance on spreadsheets: TREL’s purchasing process started with Google Sheets and later Excel, but as the demand for materials increased, the team needed a more robust order tracking process. Duplicate spreadsheets were popping up, creating confusion.

-

Long purchase approval processes: In-person purchasing meetings led to long approval processes involving multiple stakeholders; Blackwell needed to engage in several ongoing relationships at once without losing sight of the organization’s spend. “The back and forth took forever,” explains Blackwell.

-

Receiving orders across multiple locations: The combination of a multi-location organization and the reliance on static spreadsheets often left the engineering team in the dark when it came to the whereabouts of their orders.

-

Reporting spend data to investors: With reporting expectations from investors, every dollar needed to be accounted for and reported on. At the peak of their growth, managing the purchasing process through spreadsheets became overwhelming and began to jeopardize the integrity of TREL’s purchasing and financial data.

The solution

TREL needed a solution that streamlined business operations without slowing their engineers down, so they started evaluating options. Blackwell’s other workplace, an aerospace organization, was using Procurify to manage their spend. Having seen the platform previously, Bryce knew the transition from spreadsheets to Procurify would allow the team at TREL to better control their spend without slowing down their processes.

-

A centralized and single source of truth: With orders now tracked in Procurify, centralized information creates clear visibility into an organization’s spend data. Communication can now happen in one place and engineers are no longer left in the dark when it comes to the status of their orders. This reduces their time spent checking order approvals and purchases.

-

Simple onboarding and user adoption: Procurify provided an easy-to-use experience for everyone to start putting in their order requests so they can focus on designing and testing the Halcyon rocket. Chief Engineer Lauren Rodriguez explained: “I can tell the engineers had a lot of confidence after putting in their first order.

-

Tracking and receiving orders: Engineers now have transparency into the status of orders arriving at all three of their receiving locations. When somebody sees a package has arrived, they simply open the Procurify Mobile App and take a photo of the packing slip, alleviating time spent chasing and tracking down missing packages.

-

Reporting on what matters most: When reporting on the health of TREL’s finances and funding to investors, Blackwell now has reliable access to TREL’s total spend in real-time. Information required for the spend approval process with TREL’s sponsors is also now transparent and easily accessible.

Staying in control without slowing down

TREL’s mission is focused on creating the next generation of rocketeers. With Procurify, the team at TREL can focus on that mission, knowing their spend management is under control.

The team at Procurify is excited to be a part of TREL’s mission into space. We’re proud to be partnered with an organization that reflects similar core values to our own: creativity, curiosity, compassion, and most importantly, courage.