3 Ways to Embrace Today’s Procurement Best Practices

An ideal set of procurement best practices can lower labor and material costs to boost the well-being of any business, so companies should keep best practices in mind when developing strategies that will work in today’s competitive sector.

When assessing your company’s financial performance, you likely look at your revenue streams or consider the bottom line. However, in today’s competitive and unpredictable economy, managers like you are increasingly concerned about their company costs.

With an eye on reducing costs and increasing efficiencies, managers are treating procurement as a much more serious part of their business. Skilled supply chain managers—who have the ability to find the best deals around, negotiate with suppliers and ship those items to the company faster and cheaper than ever before—are in high demand.

1) Strategic Sourcing

Photo Credit: Doug

Alan Day, founder of the procurement consulting firm State of Flux, has noticed that over the last 10 years the notion of “strategic sourcing” has become more important in supply chain management. While procurement examines all the factors involved in making a supply purchase, strategic sourcing examines the whole supply network and procurement process. When making purchasing decisions, they can thus take into account risk, value creation, supply chain uncertainty and the process’s overall impact on the company.

Using strategic sourcing to make procurement decisions is the ideal scenario for large conglomerates looking to limit in-house expenses. Smaller companies are more likely to focus on traditional methods of procurement given that they have less transactions to worry about than their corporate counterparts. Still, paying more attention towards strategic sourcing can contribute to lower material costs in the long run meaning savings for your company.

2) Supplier-Consumer Partnerships

Photo Credit: Stock-Asso / Shutterstock

Although it used to be that supplier-consumer relationships were only important when companies were looking to make a deal, the relationship between the two parties needs to continue even when transactions aren’t taking place. This is especially true when suppliers have the knowledge to advise purchasers on methods related to the installation, operation, production and servicing of items.

Granted, businesses in the service sector and smaller companies who don’t rely on bulk supply orders may not place as much emphasis on partnerships simply because procurement doesn’t take place as frequently. However, good procurement employees recognize the value of the input of a supplier, whose vast knowledge could benefit the running of a company—it’s always good to have yet another person on your side.

3) Automated Technology

Photo Credit: charles taylor / Shutterstock

Technology has accelerated and sharpened the accuracy of procurement; the speed and efficiency of these automated systems save time and money, and if the right software is chosen, the whole process is remarkably simple. Technologically-driven procurement reduces purchase-to-pay bottlenecks, freeing workers up to make more strategic decisions, generate more business opportunities and focus more on solving bigger-picture issues.

Yet some organizations fail to consider that there exists a right software for their specific needs; adding any technology won’t automatically boost a business. For example, if a company in the service industry uses procurement technology designed for a goods manufacturer, it will likely experience more botched purchase orders and even loss of data critical to management decisions—the very scenario the technology was designed to avoid.

Procurement best practices will impact your profitability

While companies may incorporate some of these practices over others, what they all need to recognize is that price can’t be the sole variable in making procurement decisions. Other factors such as an item’s suitability for company operations and a company’s long-term goals also determine which procurement practices can contribute to a company’s vitality. By incorporating any of the above three practices where suitable, you’ll see an overall reduction in your in-house costs, freeing up your operations to shift more focus to the bottom line.

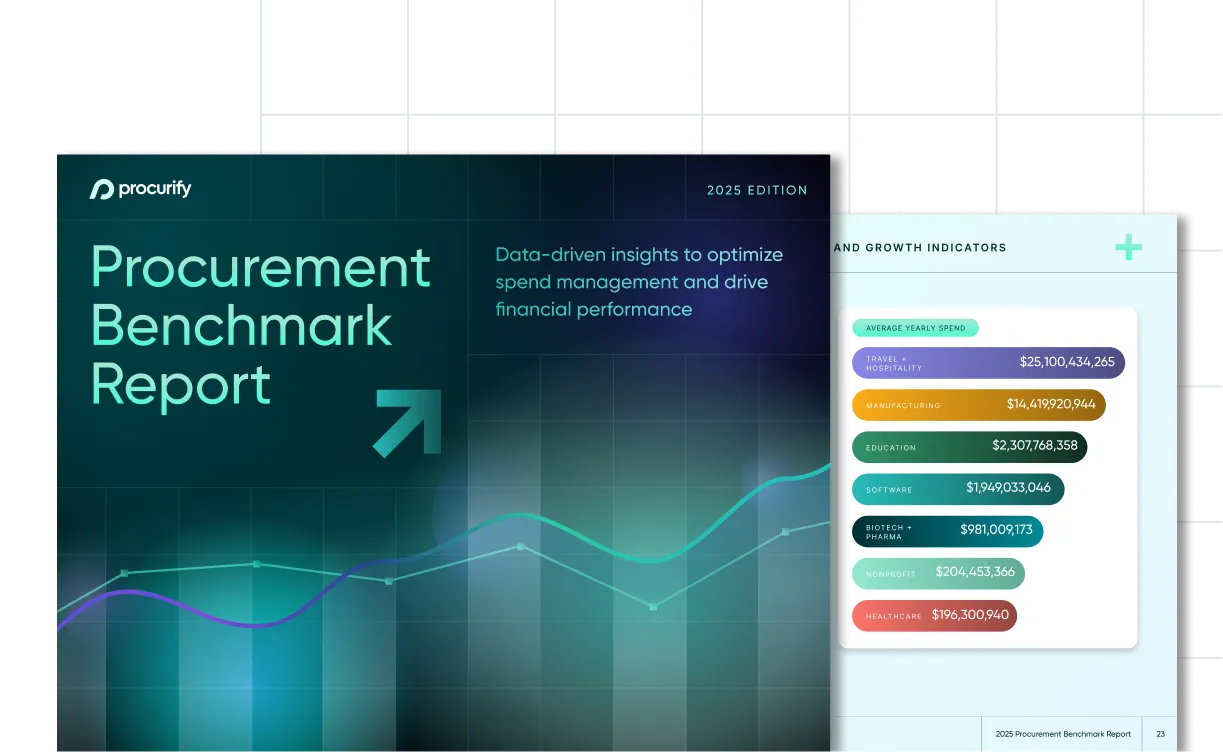

2025 Procurement Benchmark Report

Powered by $20B+ in proprietary data you won’t find anywhere else.