Procurement vs Purchasing: What’s the Difference?

Procurement and purchasing are related, but they’re not the same step in the process.

Procurement is the upstream work: defining needs, selecting suppliers, negotiating terms, and setting the rules for how spend happens. Purchasing is the downstream work: issuing POs, receiving goods/services, matching invoices, and making sure suppliers get paid.

Put simply: procurement sets the direction; purchasing carries it out. Below, we’ll break down the differences with a table and show how the handoff works inside procure-to-pay.

Purchasing: definition and responsibilities

The purchasing process is the transactional part of acquiring goods or services. It is the day-to-day work of placing orders, confirming receipt, and routing documents so suppliers can be paid accurately.

In most organizations, it looks like:

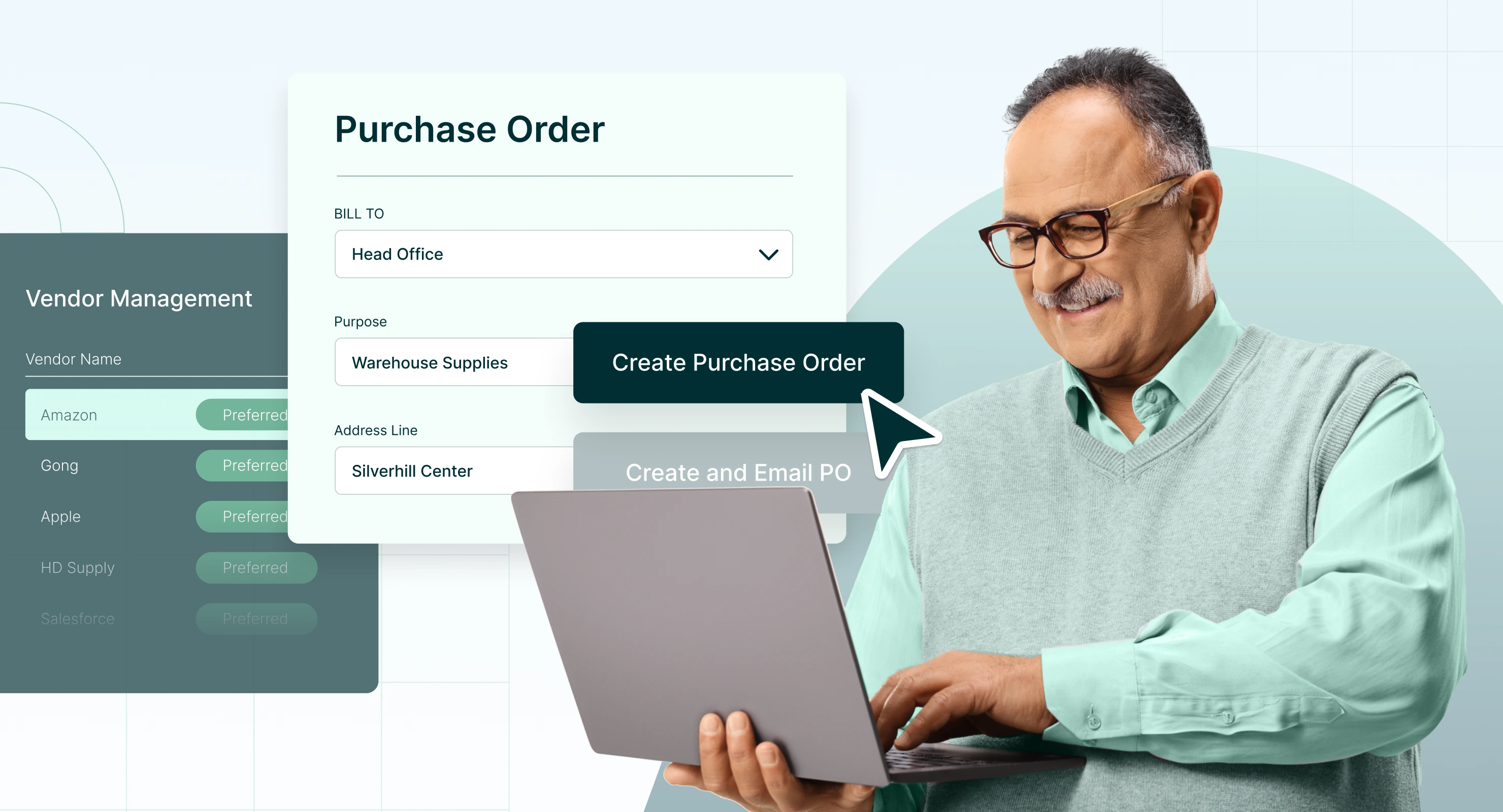

- Creating and issuing purchase orders (POs)

- Receiving goods or confirming services were delivered

- Collecting supporting documentation (receipts, packing slips, service confirmations)

- Matching the PO, receipt, and invoice (three-way match)

- Routing invoices for approval and payment

Procurement vs purchasing: Key differences

Purchasing is typically measured on execution: order accuracy, speed, and ensuring documentation is in place, so invoices

can be paid correctly, whereas procurement is often benchmarked on longer-term outcomes, such as value, risk, compliance, and supplier performance over time.

Category |

Procurement |

Purchasing |

|---|---|---|

| End goal | Identify business needs and secure the right goods/services to meet them. | Execute the purchase—place orders and ensure goods/services are acquired for the business. |

| How goods and services are assessed | Prioritizes overall value (quality, risk, service levels, total cost), not just unit price. | Often prioritizes speed and price for immediate needs and fulfillment. |

| Where it’s most beneficial | Upstream planning—standardizing suppliers, terms, and sourcing decisions. | At the point of purchase—turning approved needs into POs, receipts, and payable invoices. |

| Tasks involved | Need recognition, sourcing, vendor selection, negotiation/contracting, and ongoing governance/recordkeeping. | Ordering, PO management, follow-ups/expediting, receiving, and coordinating payment readiness. |

| How it deals with suppliers | Builds long-term supplier relationships and manages performance over time. | Focuses on efficient transactions and fulfillment for specific purchases. |

Total cost of ownership (TCO): an important consideration

One reason procurement looks beyond sticker price is total cost of ownership (TCO)—the full cost of an item over its useful life. TCO can include shipping, implementation, training, maintenance, renewals, and the operational cost of delays, errors, or exceptions. Procurement may also weigh factors like compliance, risk exposure, and supplier reliability when choosing vendors.

Think of it like this: purchasing helps you buy the right thing today; procurement helps you keep buying the right way over time.

What is important to understand is how that difference shows up in real workflows across the procure-to-pay process.

Where procurement and purchasing show up in the procure-to-pay process

Procure-to-pay (P2P) is one workflow, but it has two different jobs: make a good buying decision and execute that decision cleanly. Understanding where each function shows up and what it’s responsible for is what prevents bottlenecks, rework, and uncontrolled company spend (like off-contract buys, missing approvals, or invoices that show up with no PO trail).

Procurement’s role in P2P: shaping the decision before commitment

Procurement shows up before money is committed, when the organization is deciding what “good” looks like for a purchase: the right supplier, the right terms, and the right controls.

In P2P, procurement typically produces the things that make execution predictable:

-

Supplier standards: approved vendors, onboarding requirements, risk/compliance checks

-

Commercial terms: pricing, discounts, SLAs, payment terms, renewals, contract language

-

Buying rules: preferred suppliers, spend thresholds, approval paths, category guardrails

-

Sourcing decisions: when to single-source vs multi-source, how quotes are evaluated

What “good” looks like: fewer one-off suppliers, fewer price disputes, and fewer “we didn’t agree to that” surprises when the invoice lands.

What breaks when it’s weak: purchasing spends time chasing quotes, clarifying what was agreed, and correcting POs because the upstream decision wasn’t documented or enforced.

Purchasing’s role in P2P: executing the order and protecting the paper trail

Purchasing shows up after the decision and approvals are in place. The job here is to turn intent into a clean transaction — and to create the documentation trail that AP needs to pay accurately.

In P2P, purchasing typically owns the execution artifacts:

-

Purchase order accuracy: correct items, quantities, pricing, ship-to, coding, and terms

-

Receipt/proof: goods receipt, service confirmation, packing slips, delivery notes

-

Exception handling: backorders, substitutions, partial deliveries, change orders

-

Payment readiness: three-way match support so AP isn’t rebuilding context at the end

What “good” looks like: fewer invoice holds, fewer urgent escalations (“can we just pay this?”), and faster matching because the PO and receipt data is clean.

What breaks when it’s weak: invoices lack a PO trail, receiving is inconsistent, and price mismatches are common, making AP stop and investigate before paying.

The handoff line (the part most teams get wrong)

In procure-to-pay, the split usually looks like this:

-

If you’re deciding who to buy from, under what terms, and within what rules, that’s procurement.

-

If you’re ensuring the PO, receipt, and invoice align so payment can happen, that’s purchasing (with AP handling payment execution).

When that split isn’t followed, the “decision” doesn’t carry into the paperwork — and the mismatch shows up when someone tries to pay.

Example (off-contract buy): Marketing needs branded swag fast and picks a random vendor. Procurement has a preferred supplier with negotiated pricing and net-30 terms, but the request bypasses intake. Purchasing receives an invoice with a credit-card fee and net-7 terms — and no PO. Now AP has to chase approval after the fact, and procurement has to clean up the vendor onboarding and terms midstream. With clear roles, that request would have been routed to the preferred supplier path before the order was placed.

Common P2P failure points (and what they usually mean)

- No PO invoices: the request didn’t go through the normal buying path.

- Price/term disputes: the PO didn’t reflect agreed terms, or terms weren’t set.

- Constant 3-way match issues: receipts aren’t being recorded, or PO data is inconsistent.

- Too many one-off vendors: approved options aren’t clear, enforced, or usable.

- Slow approvals: thresholds/owners aren’t defined, or routing isn’t standardized.

How automation reduces P2P exceptions

Automation doesn’t replace procurement or purchasing. It strengthens both by making the handoff inside procure-to-pay consistent, meaning the right information is captured once, the right controls are applied at the right time, and execution doesn’t depend on memory or email threads.

Where automation helps procurement most

Automation helps by:

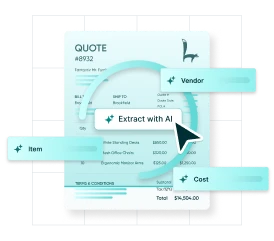

- Structuring intake so requests include the details procurement needs (category, vendor, justification, budget owner, timing)

- Applying guardrails early through purchase approval paths, spend thresholds, and preferred supplier rules

- Operationalizing sourcing for higher-risk or higher-value purchases (quotes, evaluations, and exception justification)

- Preserving negotiated terms so what was agreed (pricing, payment terms, SLAs, renewals) is reflected in how the order is placed

Where automation helps purchasing most

Purchasing is strongest when execution produces clean documentation for payment.

Automation helps by:

- Generating accurate POs from approved requests (coding, pricing, quantities, ship-to, terms)

- Making receiving consistent (goods receipt or service confirmation logged every time)

- Connecting PO → receipt → invoice so matching is rule-based, not detective work

- Routing exceptions to the right owner (price variance to the requester, missing receipt to receiving, vendor mismatch to procurement)

It is important that purchase requisitions are structured, the PO is created correctly upfront and the invoice workflow isn’t dependent on someone tracking down context later.How do you keep track of all purchasing activities?

How to keep purchasing activity organized

Keeping track of purchasing activity matters because it’s the record of what was ordered, what was received, and what should be paid.

To keep that trail reliable, teams usually standardize a few basics:

- One place to track POs, receipts, and invoices, instead of splitting context across email, shared drives, and spreadsheets

- Consistent receiving, so goods or services are confirmed the same way every time

- Clear matching rules, so it’s obvious what has to line up before an invoice moves forward

- Clear ownership for issues, like price changes, partial deliveries, missing receipts, or vendor mismatches

When those basics are in place, invoices move with fewer stops, approvals aren’t based on guesswork, and finance doesn’t have to reconstruct history during close or audit.

Procurement and purchasing: where they intersect

Procurement and purchasing intersect when a buying decision becomes a payable transaction. That intersection shows up when an approved request becomes a purchase order that carries the right supplier, pricing, and terms forward, and again when the invoice is checked against what was originally agreed. If that handoff breaks, strategy stays theoretical and execution turns reactive.

They also intersect when real-world exceptions occur. Shipments change, prices don’t match, or a different supplier is used. Purchasing encounters those issues first in the workflow, but procurement owns the decision about whether the change is acceptable or needs correction. When that intersection is clear, exceptions are resolved quickly. When it isn’t, problems surface when they’re hardest to fix.

If you want to see how mature your handoff is today (and what to fix first), the Procurement Maturity Model benchmarks your current approach and highlights the quickest path to fewer exceptions.

Preview AI Intake for Orders

Take the product tour to see how the new intake experience works.