The Difference Between Procurement and Supply Chain Management

Procurement and supply chain management are often used interchangeably, but they play very different roles in how organizations operate. Understanding the distinction helps finance and operations teams improve efficiency, reduce costs, and strengthen supplier relationships. Here’s how they differ — and why both are essential.

TL;DR: Procurement vs Supply Chain Management

- Procurement focuses on buying the right goods and services at the right terms.

- Supply Chain Management (SCM) focuses on moving and managing everything from suppliers to customers.

- Procurement lives inside SCM — together they drive efficiency, cost control, and business continuity

| Dimension | Procurement | Supply Chain Management |

|---|---|---|

| Goal | Acquire goods and services efficiently | Optimize flow from supplier to customer |

| Scope | Sourcing, contracts, purchase orders, payments | Forecasting, production, logistics, inventory, returns |

| Time Horizon | Near to mid-term | Mid to long-term |

| KPIs | Cost savings, supplier performance, compliance | Delivery speed, cost efficiency, inventory turns |

| Core Question | “Are we buying the right thing at the right price?” | “Is our entire process running efficiently end to end?” |

Understanding procurement’s role and process in the supply chain

Definition and purpose of procurement.

Procurement is the process by which organizations source and acquire the goods and services they need. It involves identifying needs, finding suppliers, negotiating terms, and ensuring on-time delivery — all to secure the best value and align purchasing with business goals.

Curious how procurement differs from purchasing? Check out our guide on Procurement vs. Purchasing for a closer comparison.

Key Procurement Activities and Steps

Procurement typically includes:

-

Identifying organizational needs

Before any purchases are made, procurement teams determine what the organization requires — whether to address a shortage, support a new project, or meet ongoing operational needs.

-

Researching and selecting suppliers

Teams evaluate potential suppliers based on price, quality, reliability, and reputation to find the best fit for organizational needs.

-

Negotiating pricing and terms

Procurement negotiates price, quantity, timelines, and payment terms to ensure the best value and minimize risk.

-

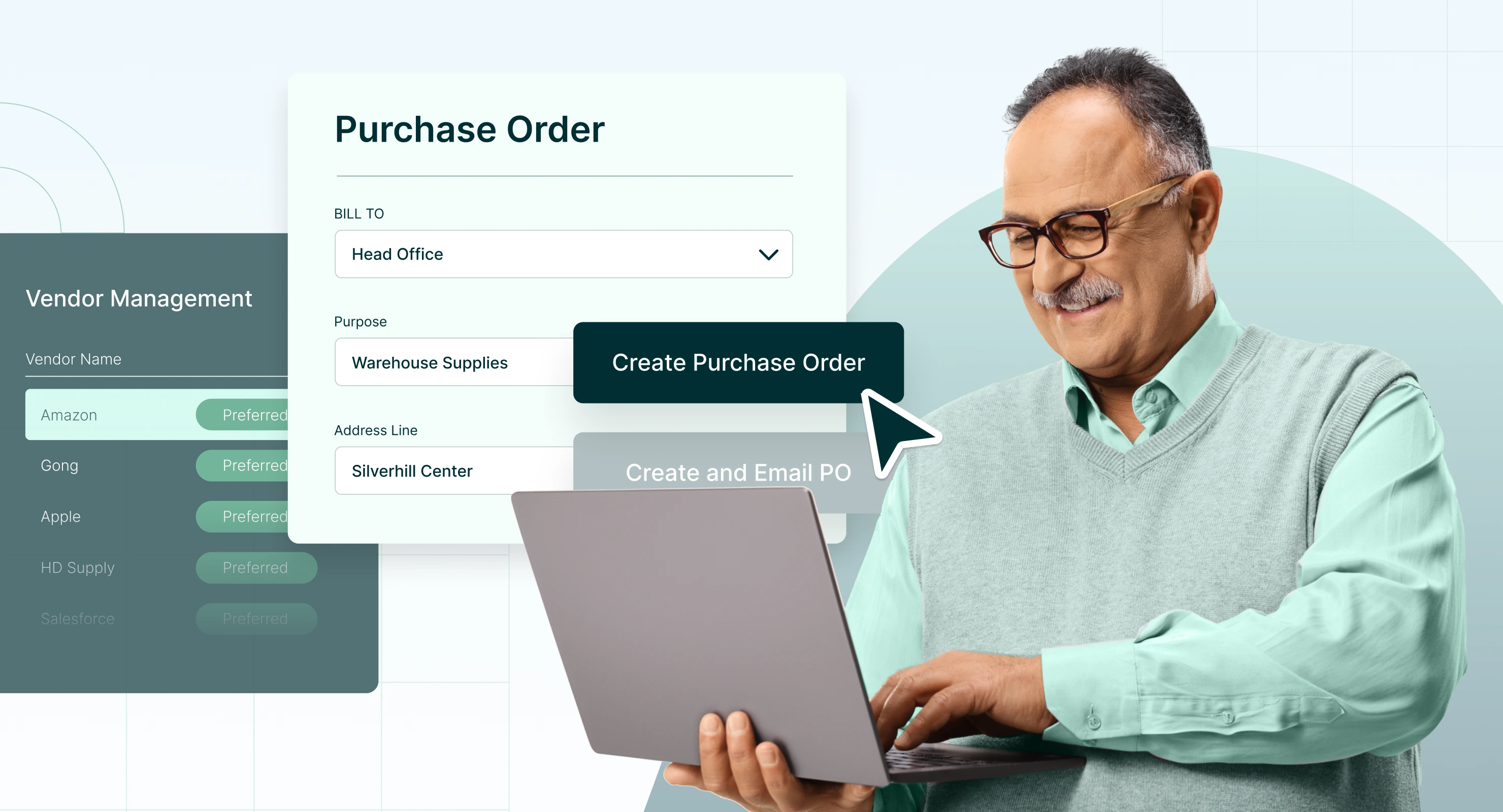

Purchase Order Issuance

A purchase order (PO) formalizes the agreement, confirming the details of what’s being bought and under what terms.

-

Delivery and Inspection

Upon receipt, goods or services are inspected to verify they meet quality and specification requirements.

-

Invoice Processing and Payment

After verifying delivery and quality, the procurement team processes invoices and ensures suppliers are paid on time.

-

Supplier Relationship Management

Strong, long-term supplier relationships can yield better pricing, reliability, and innovation opportunities.

-

Contract Management

For ongoing or high-value purchases, procurement monitors contract performance and compliance, renegotiating as needed.

-

Risk Management

Teams identify and mitigate risks such as supplier failure, cost fluctuations, or geopolitical disruptions.

-

Review and Analysis

Regularly reviewing supplier performance and internal processes helps uncover inefficiencies and cost-saving opportunities.

Why Procurement Matters to Business Performance

Procurement ensures every purchase supports the company’s objectives — balancing cost, quality, compliance, and supplier performance.

The Role of Procurement in an Organization

-

Strategic Sourcing & Cost Savings

Procurement secures the right goods and services at the best value, aligning purchases with organizational goals and ensuring financial efficiency.

-

Risk Management & Compliance

Teams anticipate supply risks, manage contracts, and maintain compliance with regulations and ethical standards.

-

Sustainability & Ethics

Modern procurement prioritizes environmental impact, ethical sourcing, and social responsibility alongside cost and quality.

-

Supplier Relationship Management

Strong partnerships lead to better collaboration, innovation, and long-term value creation.

-

Innovation & Data-Driven Insight

By analyzing spend data and supplier performance, procurement uncovers opportunities for continuous improvement and business growth.

In short: Procurement defines how money moves through the business — controlling costs, improving supplier performance, and turning spending data into strategic advantage.

Understanding supply chain management (SCM) and its objectives

Definition of Supply Chain Management

Supply Chain Management (SCM) is the coordination of people, activities, information, and resources that move a product or service from supplier to customer. It covers the entire process — from sourcing raw materials to delivering finished goods — ensuring efficiency, quality, and customer satisfaction.

Objectives and Goals of Supply Chain Management

-

Efficiency and Speed:

Streamline the flow of goods and services to minimize waste and reduce time to market.

-

Cost Reduction:

Lower operating costs across the supply chain without compromising quality or service.

-

Quality Improvement:

Maintain consistent quality standards at every stage, from production to delivery.

-

Flexibility and Adaptability:

Build a supply chain that can quickly respond to changes in demand, supply, or logistics.

-

Collaboration and Integration:

Improve coordination between suppliers, manufacturers, and distributors for seamless operations.

-

Risk Mitigation:

Identify potential disruptions early and develop strategies to minimize their impact.

-

Sustainability:

Operate responsibly by integrating ethical and environmental considerations into supply chain decisions.

-

Customer Satisfaction:

Ensure timely, reliable, and high-quality delivery to meet customer expectations.

-

Innovation:

Use new technologies and ideas to enhance efficiency and competitiveness.

-

Visibility and Control:

Achieve end-to-end transparency to make data-driven decisions and manage performance proactively.

By meeting these objectives, SCM creates a competitive advantage — aligning operations, cost control, and customer value in one unified system.

Core components of the supply chain explained

While procurement focuses on sourcing and purchasing, supply chain management connects every stage that follows — from raw materials to final delivery. Understanding these core components is vital for maintaining an efficient, adaptable, and customer-focused supply chain.

-

Suppliers:

Provide the raw materials, components, or services essential for production. Strong, reliable supplier relationships are critical for maintaining quality and continuity.

-

Manufacturers:

Transform raw materials into finished goods. Their efficiency and quality control determine much of the supply chain’s overall performance.

-

Warehousing:

Balances supply and demand by storing goods until needed. Effective warehousing ensures availability while reducing overstock and carrying costs.

-

Distribution Centers:

Serve as hubs for sorting, consolidating, and directing goods to various destinations, streamlining delivery across regions or markets.

-

Transportation:

Covers the logistics of moving products by truck, ship, air, or rail. It’s the connective tissue that keeps the entire supply chain flowing.

-

Retailers:

Sell finished goods to customers, whether in-store or online, acting as the supply chain’s public-facing end point.

-

Customers:

The end users whose expectations and behavior shape demand, influencing every upstream decision.

-

Return Management:

Also called reverse logistics, this covers returns, exchanges, and recycling — increasingly vital for sustainability and customer satisfaction.

-

Information Technology Systems:

Enable real-time communication, tracking, and analytics across the supply chain, supporting transparency and data-driven decisions.

-

Human Resources:

The people who plan, manage, and execute operations at every stage. Their skills and coordination ensure everything runs smoothly.

When these components work together seamlessly, they create a supply chain capable of meeting demand efficiently, reducing costs, and delivering consistent value to customers.

Why effective supply chain management is a strategic advantage

Effective Supply Chain Management (SCM) goes beyond moving materials — it’s a strategic lever for cost control, resilience, and growth. Here’s how it drives competitive advantage:

-

Cost Efficiency:

A well-optimized supply chain minimizes waste, balances inventory, and leverages economies of scale. These efficiencies reduce costs and strengthen margins without sacrificing quality.

-

Customer Satisfaction:

SCM shapes customer experience. Agile supply chains meet demand quickly, ensuring products arrive on time and in full — building reliability and trust.

-

Adaptability in Market Shifts:

Markets shift constantly. Effective SCM enables rapid response to supply disruptions, demand swings, and evolving customer expectation.

-

Quality Control:

End-to-end visibility allows organizations to monitor and maintain product quality across every stage — protecting both brand and customer loyalty.

-

Innovation Enablement:

When supply chains run smoothly, teams can focus on R&D and innovation. SCM provides the operational stability needed to bring new products to market faster.

-

Risk Mitigation:

Strong supply chains anticipate and prepare for disruptions — from supplier failures to regulatory changes — ensuring business continuity.

-

Sustainability and Compliance:

Modern SCM integrates environmental and ethical standards into sourcing, manufacturing, and logistics, aligning operations with stakeholder expectations.

-

Global Reach:

Effective SCM supports international expansion by managing logistics, compliance, and regional partnerships at scale.

In essence: SCM isn’t just a support function — it’s a driver of profitability, innovation, and long-term resilience.

Procurement vs. supply chain management: Detailed comparison

Procurement and supply chain management (SCM) are closely connected but serve different purposes within an organization. Procurement focuses on acquiring the goods and services a business needs — from identifying suppliers to negotiating contracts and ensuring value for money.

Supply chain management, on the other hand, covers the entire journey of those goods and services — from raw materials to final delivery. It connects procurement with production, logistics, and distribution to keep operations efficient and aligned with customer demand.

Put simply: procurement is a part of the supply chain, but SCM is the system that makes the entire flow work.

Quick Comparison: Procurement vs. Supply Chain Management

| Aspect | Procurement | Supply Chain Management (SCM) |

|---|---|---|

| Focus | Acquiring goods and services | Managing the full flow from suppliers to customers |

| Scope | Individual function (sourcing, purchasing, payments) | End-to-end process (production, logistics, delivery) |

| Objective | Cost savings, supplier relationships, value for money | Efficiency, responsiveness, and customer satisfaction |

| Responsibility | Select and manage suppliers | Coordinate suppliers, manufacturers, and distributors |

| Time Horizon | Short- to mid-term | Mid- to long-term strategic focus |

| Metrics | Purchase cost, supplier performance, savings | Lead times, service levels, inventory turnover |

| Tools/Systems | Procurement software, POs, contract management | ERP, supply chain planning, logistics systems |

Scope of Activities: Individual Process vs. End-to-End System

Procurement operates with a focused scope. It centers on the specific steps of selecting suppliers, negotiating contracts, and purchasing the goods and services an organization needs. While it’s a subset of the broader supply chain management system, procurement software solutions play a crucial role in ensuring value, compliance, and operational efficiency.

Its key activities include:

-

Identifying needs: Determining what the organization requires to operate effectively.

-

Sourcing materials and services: Finding and evaluating suppliers based on quality, cost, and reliability.

-

Negotiating prices and terms: Setting purchase conditions that balance value and cost efficiency.

-

Making purchases: Issuing purchase orders and securing goods or services.

-

Ensuring quality and compliance: Verifying that purchased items meet standards and contractual terms.

The procurement process typically ends once goods or services are delivered and paid for, underscoring its focused, transactional nature within the larger supply chain.

How SCM Manages the Entire Lifecycle

Supply chain management (SCM) has an expansive, end-to-end scope that covers every stage of a product’s journey — from sourcing raw materials to production, distribution, and final delivery. SCM integrates procurement with manufacturing, logistics, and distribution to create a seamless flow of goods and services across the entire value chain.

Key SCM activities include:

- Integrating procurement and production processes

- Managing logistics and distribution networks

- Coordinating suppliers, manufacturers, and retailers

- Ensuring efficient delivery and customer satisfaction

By taking this holistic view, SCM balances supply and demand, minimizes costs, and optimizes performance across the business. In essence, procurement handles what to buy, while SCM manages how it moves — a distinction that defines their different scopes.

Strategic vs. Operational Focus

Procurement is often viewed through an operational lens, focusing on daily purchasing activities — sourcing, contracting, supplier management, and negotiation. Its goal is to ensure the organization gets the right materials, at the right time, at the right price.

SCM, by contrast, is strategic. It coordinates the full supply network, builds long-term resilience, and uses technology and forecasting to align operations with business goals. Effective SCM looks ahead — designing systems that can anticipate risk, enable agility, and support sustainable growth.

Together, procurement’s operational excellence and SCM’s strategic oversight ensure short-term efficiency and long-term success.

Objectives and End Goals Compared

Procurement’s objectives center on cost control and value delivery — negotiating favorable terms, ensuring supplier quality, and managing purchasing risk to protect profitability.

SCM’s objectives are broader, focused on optimization and customer value. It enhances efficiency, reduces total costs, drives innovation, and maintains agility to respond to shifting demand.

In short, procurement’s goal is to buy smart; SCM’s goal is to build systems that keep the entire business running smarter.

How SCM Drives Optimization Across the Business

In contrast, the objectives of supply chain management (SCM) are broad and integrated, focused on optimizing the entire value chain. SCM aims to:

-

Ensure a seamless, efficient flow of goods from suppliers to customers

-

Enhance customer satisfaction through reliable delivery and service

-

Reduce total costs through better planning and supply chain design

-

Increase agility to respond quickly to market changes

-

Drive innovation across products, processes, and partnerships

The ultimate goal of SCM is to build a sustainable competitive advantage — not only by minimizing costs, but by maximizing value for customers and the business alike.

This distinction underscores procurement’s role in cost control and SCM’s influence on overall efficiency, innovation, and long-term performance.

How procurement fits into the supply chain: Bridging strategy and execution

Procurement plays a vital role within supply chain management (SCM), connecting day-to-day purchasing decisions with long-term business strategy. It ensures that every buying decision — from supplier selection to contract negotiation — supports broader goals of efficiency, resilience, and cost control.

When procurement is aligned with SCM strategy, organizations gain more than operational efficiency. They achieve visibility into spend, stronger supplier collaboration, and the agility to adapt when markets shift. Integrating procurement into the supply chain allows companies to manage resources proactively — not reactively — and to create a continuous feedback loop between sourcing, production, and distribution.

The Role of Procurement Within the Broader Supply Chain

Procurement is the entry point of the supply chain — responsible for sourcing the goods and services that fuel operations. Its influence extends well beyond purchasing; it shapes cost structures, supplier reliability, and the quality of every downstream process.

As part of SCM, procurement functions as the strategic arm that secures and manages supplier partnerships, mitigates risk, and ensures the uninterrupted flow of materials and information. Working hand-in-hand with logistics, inventory, and planning teams, procurement helps balance cost efficiency with flexibility and innovation.

In essence, procurement is the foundation of an effective supply chain. When executed strategically, it enhances visibility, controls costs, and strengthens an organization’s ability to respond to changing demand — turning purchasing into a key driver of long-term competitiveness.

How Procurement Decisions Shape the Supply Chain

Procurement and supply chain management (SCM) are deeply interconnected. Every purchasing decision can influence production, logistics, and delivery, while supply chain performance can shape procurement strategy in return.

Impact of Procurement Decisions on the Supply Chain

- Quality Control: Supplier selection directly affects the quality of materials and components. Strong procurement practices lead to better end products, fewer delays, and higher customer satisfaction.

- Cost Management: Negotiated prices and payment terms have a direct impact on the cost of goods sold (COGS) and overall profitability.

- Inventory Management: Procurement timing and contract flexibility determine how efficiently inventory is managed. Just-in-time purchasing, for example, minimizes holding costs but requires highly reliable suppliers.

- Risk Mitigation: Diversifying suppliers and building contingency plans protect the supply chain from disruptions caused by market, political, or environmental factors.

How Supply Chain Factors Influence Procurement

-

Demand Planning: Sales forecasts and inventory data inform procurement’s timing and volume decisions, aligning purchases with actual demand.

-

Supplier Relationship Management (SRM): Ongoing supply chain performance feedback helps procurement identify top-performing suppliers and address underperformance early.

-

Technology and Innovation: As supply chain systems evolve, procurement must adapt — sourcing new technologies, renegotiating contracts, and ensuring supplier readiness for digital transformation.

Why Procurement-SCM Alignment Matters

Procurement doesn’t operate in isolation. When procurement and SCM strategies are aligned, organizations gain visibility, efficiency, and agility — anticipating issues before they escalate and optimizing total cost of ownership.

Conversely, when procurement acts without considering the broader supply chain, inefficiencies, delays, and missed opportunities follow. Integration between these functions isn’t optional — it’s the foundation of a resilient, high-performing business.

How procurement and supply chain management work together

Procurement and supply chain management (SCM) don’t operate in silos — they function as two halves of the same system. Procurement decisions shape what enters the supply chain, while SCM determines how those inputs move, transform, and reach customers. Together, they create the foundation for cost efficiency, agility, and sustained business performance.

When these functions work in sync, organizations gain tighter control over costs, improve supplier collaboration, and respond faster to market shifts. Misalignment, on the other hand, can cause ripple effects — from production delays to inflated expenses and lost opportunities.

The following real-world examples highlight how strong collaboration between procurement and SCM drives resilience, efficiency, and competitive advantage — and what can happen when that alignment breaks down.

Lessons from businesses that integrated procurement and supply chain strategy

The connection between procurement and supply chain management (SCM) becomes clearest in practice. The examples below show how alignment between the two can drive efficiency and growth — and how gaps between them can quickly create costly setbacks.

Case study 1: SaaS and technology

For instance, a fast-scaling technology company discovered that managing purchases through spreadsheets and emails limited visibility across teams and delayed approvals. By streamlining procurement workflows and integrating them with financial systems, the organization improved supply chain coordination, accelerated purchasing cycles, and gained real-time visibility into company-wide spend

Case study 2: Biotech and healthcare

The biotech industry offers some of the clearest examples of procurement and supply chain alignment. For instance, Moderna’s vaccine production required sourcing temperature-controlled packaging and coordinating with logistics partners to maintain ultra-cold storage conditions. Procurement teams secured reliable suppliers and materials, while supply chain teams monitored every shipment in real time — ensuring compliance, product integrity, and uninterrupted distribution.

Case study 4: Education Sector – Charter School Networks

Charter schools face unique challenges when it comes to procurement and supply chain management. With limited budgets and decentralized campuses, even small purchasing inefficiencies can multiply quickly.

When a charter school network shifted from traditional textbook orders to digital learning tools, its procurement team partnered with approved vendors and education platforms to streamline sourcing and ensure curriculum alignment. By centralizing purchasing and coordinating with supply chain partners for delivery and licensing, the network reduced costs, gained better visibility into spending, and equipped classrooms faster — all while supporting a more sustainable, tech-ready learning environment.

Case study 5: Manufacturing

In manufacturing, decentralized procurement and manual approvals often slow down production. The chemical manufacturing firm PSC Group, operating across dozens of plants, struggled with inconsistent purchasing, delayed supplier payments, and limited visibility into company-wide spend.

By centralizing approvals and digitizing its procure-to-pay process, the company cut processing times, improved compliance, and gained real-time insight into supplier performance. Procurement and supply chain teams now work in sync—keeping materials moving efficiently and freeing staff to focus on higher-value work.

These examples show that when procurement and supply chain management work in sync, organizations gain more than efficiency — they build resilience, agility, and a foundation for long-term growth. Aligning the two functions turns purchasing data into strategic insight, strengthens supplier relationships, and creates the visibility needed to stay competitive in any market.

Key benefits of aligning procurement and SCM strategies

Aligning procurement and supply chain management (SCM) creates a more resilient, cost-effective, and agile organization—one that can respond more quickly to change and drive long-term growth.

Increased Productivity and Reduced Costs

-

Streamlined Processes:

Integration of procurement with SCM helps in standardizing processes which, in turn, reduces administrative overheads and simplifies operations.

-

Volume Consolidation:

Leveraging total spend through coordinated procurement leads to better negotiation and reduced costs.

-

Reduced Waste:

A more synchronized approach between procurement and the supply chain can lead to reductions in over-ordering and underutilizing resources, thereby minimizing waste.

Improved Supplier Relationships

-

Strategic Sourcing:

Joint strategies enable the development of long-term relationships with suppliers, which can lead to more reliable supply chains and opportunities for innovation.

-

Collaborative Partnerships:

Working closely with suppliers can lead to collaborations that improve product quality and the overall value proposition for the end customer.

Risk Mitigation

-

Greater Visibility:

Aligned procurement and SCM facilitate better visibility throughout the supply chain, enabling early detection of potential disruptions and quicker responses to market changes.

-

Diversification:

A unified approach allows for better risk assessment and the diversification of suppliers, reducing the dependency on single sources.

Quality Improvement

-

Standardization:

Coordinated strategies can lead to standardization of inputs, resulting in consistent quality of the end products or services.

-

Compliance:

With procurement and SCM working together, compliance with regulations, standards, and corporate policies is more effectively managed.

Innovation and Growth

-

Market Adaptability

An integrated approach helps organizations to be more adaptive to market demands and changing consumer preferences.

-

Innovation Through Collaboration

By aligning procurement with SCM, companies can engage suppliers in the innovation process, potentially leading to breakthroughs in products, services, or processes.

Customer Satisfaction

-

Reliable Fulfillment

A seamless supply chain ensures that customer demands are met promptly and reliably, leading to higher customer satisfaction.

-

Value Addition

The cost savings and efficiencies gained from alignment can be used to add value to the customer, either through lower prices or better service offerings.

Sustainability

-

Ethical Sourcing

Working in tandem, procurement and SCM can prioritize ethical sourcing practices, contributing to the company’s social responsibility goals.

-

Environmental Impact

Coordinated efforts often lead to reduced carbon footprints due to optimized logistics and waste reduction, aligning with sustainability targets.

When procurement and SCM operate as one, organizations move from reactive to strategic — cutting waste, improving visibility, and turning operational efficiency into a lasting competitive advantage.

The future of procurement and supply chain management

Procurement and supply chain management are evolving faster than ever. Technology, new skill sets, and growing sustainability goals are redefining how organizations buy, manage, and deliver value. The future will belong to teams that can blend these forces into smarter, more adaptive, and data-driven operations.

How Technology Is Transforming Procurement and SCM

Technology now sits at the core of modern procurement and supply chain strategy. From predictive analytics to AI-driven automation and purchasing, digital innovation is turning traditional, reactive processes into proactive systems that anticipate needs and prevent disruptions before they occur.

-

AI and Automation

Robotic process automation (RPA) and artificial intelligence (AI) have streamlined procurement processes, minimizing manual tasks and reducing errors. AI algorithms now predict demand more accurately, optimize purchasing, and enhance inventory management, making procurement more proactive than reactive.

AI is also helping organizations identify spending anomalies and uncover cost-saving opportunities by analyzing large volumes of purchasing data in real time. It can flag unusual transactions, detect duplicate invoices, and reveal supplier pricing trends that may indicate inefficiencies or hidden savings. These insights allow finance and procurement teams to act faster, negotiate better terms, and make more strategic spend decisions.

-

Blockchain for Transparency:

Blockchain technology has introduced an unprecedented level of transparency and security in SCM. By providing a tamper-proof ledger, blockchain allows for secure and transparent tracking of products from origin to end-user, significantly reducing the risks of fraud and counterfeit goods.

-

Internet of Things (IoT):

IoT devices facilitate real-time monitoring of goods across the supply chain. Sensors and smart tags enable the tracking of shipments, monitor storage conditions, and help manage inventory through just-in-time delivery systems, drastically improving efficiency.

-

Advanced Analytics

Big data and predictive analytics are enabling procurement professionals to make more informed decisions. By analyzing large datasets, companies can identify purchasing trends, assess supplier performance, and mitigate risks before they become critical issues.

-

Cloud Computing:

The adoption of cloud-based procure-to-pay solutions ensures that data is accessible from anywhere, at any time. This flexibility allows for better collaboration between departments and across geographies, enhancing the responsiveness of procurement activities.

These technologies are not just improving efficiency — they’re changing the role of procurement and supply chain professionals entirely. What once relied on transactional processing now depends on strategic insight, data literacy, and cross-functional collaboration.

The Shift Ahead

As automation takes on the repetitive, human judgment becomes even more valuable. Procurement and supply chain leaders will need to master analytics, supplier strategy, and sustainability — not just process execution. The next generation of teams will be defined by their ability to use data to make smarter, faster, and more ethical decisions.

The evolving roles and challenges in procurement and SCM

As procurement and supply chain management become more strategic, the people driving these functions are transforming too. The modern professional isn’t just a buyer or logistics expert — they’re a strategist, risk manager, and data storyteller rolled into one.

Emerging Roles in the Modern Supply Chain

-

Strategic Leaders: Procurement and supply chain professionals now influence company-wide goals, connecting operational execution with financial strategy.

-

Risk Managers: With global disruptions on the rise, teams must anticipate supplier risks, diversify sources, and build resilience into every link of the supply chain.

-

Data Translators: Analytics and automation have made data literacy essential. Turning real-time insights into smarter forecasts and decisions is now a core skill.

-

Relationship Builders: Supplier partnerships are shifting from transactional to collaborative — driving innovation, reliability, and shared sustainability goals.

New Challenges Shaping Procurement and SCM

-

Cybersecurity Risks: Digital supply chains expose organizations to new vulnerabilities. Protecting data integrity is now part of procurement’s mandate.

-

Sustainability Pressure: Organizations are expected to ensure every purchase aligns with ethical, environmental, and social responsibility standards.

-

Global Complexity: Supply chains span continents, creating challenges around regulations, logistics, and cultural nuances.

-

Talent and Agility Gaps: The field is changing faster than the talent pipeline. Future-ready teams need people who are adaptable, tech-savvy, and comfortable with change.

Procurement and SCM are no longer about managing transactions — they’re about managing transformation. Success now depends on continuous learning, digital fluency, and the ability to see how every operational decision impacts the bigger business picture.

Building sustainable and ethical supply chains

Sustainability and ethics have become central to how procurement and supply chain teams operate. No longer “nice to have,” responsible sourcing and transparent operations are now essential for long-term growth, regulatory compliance, and brand trust.

Building Sustainable Supply Chains

Modern procurement teams are rethinking how goods are sourced, produced, and delivered.

- Sourcing for Impact: Organizations increasingly choose suppliers who minimize environmental impact through renewable energy use, waste reduction, and low-emission logistics.

- Designing for Circularity: Procurement plays a key role in enabling circular supply chains — sourcing materials and products that can be reused, repaired, or recycled to reduce waste and dependency on virgin resources.

- Lifecycle Thinking: Instead of focusing solely on purchase price, procurement teams now assess total lifecycle impact — from raw material extraction to end-of-life disposal — to make decisions that reduce environmental footprint over time.

How to Embed Ethics into Procurement Decisions

Ethical procurement goes beyond compliance — it defines how an organization treats people, communities, and partners.

- Fair Labor and Human Rights: Companies are holding suppliers accountable for fair pay, safe working conditions, and responsible labor practices across all tiers of the supply chain.

- Integrity and Transparency: Strong anti-corruption standards, clear governance, and transparent reporting help preserve trust and prevent reputational damage.

- Supplier Diversity: Expanding the supplier base to include small, minority-owned, and women-owned businesses not only promotes equity but also drives innovation through diverse perspectives

Overcoming Sustainability Challenges in SCM

- Visibility and Traceability: True sustainability requires deep visibility — often several tiers beyond direct suppliers. Digital tools and supplier mapping are making this more achievable.

- Balancing Cost and Value: While ethical sourcing may appear more expensive upfront, it often leads to long-term gains in efficiency, resilience, and customer loyalty.

- Engaging Suppliers: Sustainable progress depends on collaboration. Leading organizations invest in supplier education, joint improvement programs, and incentives for better environmental and social performance.

The Bottom Line

Sustainable and ethical procurement isn’t just about doing good — it’s about building smarter, more resilient businesses. When organizations align values with operations, they reduce risk, foster innovation, and strengthen customer trust. The companies that lead on sustainability today are building supply chains designed to last tomorrow.

Best practices for integrating procurement and supply chain management

When procurement and supply chain management (SCM) work in sync, organizations unlock faster operations, stronger supplier partnerships, and clearer visibility across the entire value chain. True integration isn’t about merging processes — it’s about aligning goals, technology, and teams.

Collaborative Strategies for Stronger Integration

-

1. Foster Collaboration Across Functions

Break down silos by creating cross-functional teams where procurement, finance, and operations collaborate from planning to execution. Shared KPIs — like total cost of ownership, on-time delivery, and supplier performance — help unite everyone around measurable outcomes, not departmental wins.

-

2. Leverage Unified, Data-Driven Platforms

Integration starts with visibility. Cloud-based procurement and SCM platforms provide a shared source of truth, connecting purchasing, inventory, logistics, and finance. Real-time data helps teams anticipate disruptions, manage inventory proactively, and make faster, smarter decisions.

Emerging technologies amplify this:

-

AI and analytics predict demand and optimize purchasing.

-

Integration tools connect ERP, procurement, and logistics systems.

-

Supplier portals streamline collaboration and transparency.

-

Blockchain improves traceability for compliance and trust.

-

-

3. Align Culture, Skills, and Strategy

Technology alone doesn’t drive integration — people do. Encourage knowledge-sharing between teams, invest in training for digital and analytical skills, and create a culture where both procurement and SCM see themselves as part of one continuous process delivering value to the customer.

-

4. Extend Collaboration Beyond Your Walls

Leading organizations treat suppliers as partners, not vendors. Joint innovation projects, shared improvement goals, and transparent communication build a supply network that’s more resilient and adaptable to change.

The Bottom Line

Integrated procurement and supply chain functions don’t just reduce costs — they create agility. When data, processes, and people work together seamlessly, organizations can anticipate market shifts, innovate faster, and drive long-term competitive advantage.

Essential Tools and Technology for Unified Operations

Technology is the backbone of modern procurement and supply chain management. The right systems don’t just automate tasks — they connect data, people, and processes into one intelligent ecosystem that drives visibility, agility, and strategic growth.

Core Systems That Power Integration

-

E-Procurement Platforms: Automate purchasing workflows, centralize spend data, and make it easier to manage suppliers — ensuring procurement aligns with overall supply chain goals.

-

Supply Chain Management Software: Provides real-time visibility from production to delivery, helping teams balance inventory, anticipate delays, and adapt to demand shifts.

-

Integration Tools: Ensure your ERP, procurement, and logistics systems “talk” to each other — creating a seamless flow of information across departments.

Emerging Technologies Transforming Efficiency

-

AI and Advanced Analytics: Predict demand, optimize inventory, and identify cost-saving opportunities before they appear.

-

Blockchain: Enhances trust and transparency through tamper-proof records of product origins, movements, and transactions.

-

Cloud Collaboration: Gives global teams real-time access to data, approvals, and reports — anywhere, anytime.

-

Mobile Solutions: Bring agility to the field, allowing managers and teams to approve, track, and act on spend decisions on the go.

The Strategic Value

When these tools work together, they create more than efficiency — they create intelligence. Integrated technology ecosystems give organizations the agility to respond to disruption, the insight to make proactive decisions, and the control to manage spend strategically across every link of the supply chain.

Training and Development for Modern Procurement Teams

Technology and process alignment mean little without people who can use them effectively. The future of procurement and supply chain management depends on teams who understand both functions — and have the skills to connect them.

Foster a Continuous Learning Culture

Integration requires curiosity. Encourage teams to stay ahead of industry shifts, digital tools, and best practices through ongoing training and learning opportunities. A culture that rewards learning helps organizations stay agile in the face of constant change.

Invest in Cross-Functional Skills

The most effective professionals today understand the full value chain. Joint workshops and team exchanges between procurement, finance, and operations help employees see how their work impacts the end-to-end process — breaking silos and building empathy across teams.

Leverage Modern Learning Platforms

Digital training tools make development scalable and accessible. E-learning programs, webinars, and certifications allow employees to upskill in areas like data analytics, risk management, negotiation, and supplier collaboration — anytime, anywhere.

Develop Future Leaders

Integration thrives under leaders who can think systemically. Invest in leadership programs that build strategic, tech-savvy managers capable of guiding cross-functional teams and driving continuous improvement.

Create a Feedback Loop

Regular assessments, coaching, and mentoring ensure employees are not only learning but applying new skills. This feedback-driven approach keeps development relevant to real organizational goals.

The Takeaway

Integration is powered by people, not just systems. By equipping teams with cross-functional knowledge and future-focused skills, organizations strengthen collaboration, innovation, and the ability to adapt — turning their workforce into a competitive advantage.

Conclusion: Turning procurement and SCM alignment into competitive advantage

Procurement and supply chain management are no longer separate disciplines — they’re two sides of the same strategy. Procurement ensures organizations spend wisely; supply chain management ensures those investments deliver value. When they work together, businesses gain the visibility, agility, and control needed to stay competitive in a rapidly changing world.

The key is integration — aligning technology, people, and processes around shared goals. Cloud platforms, automation, and AI now make that alignment possible in real time. AI, in particular, enhances financial planning and spend visibility by turning raw purchasing data into predictive insights — helping organizations forecast budgets more accurately, spot inefficiencies early, and make smarter decisions about where every dollar goes.

The future belongs to organizations that treat procurement and SCM as a unified ecosystem — one that connects spend decisions to operational outcomes. By investing in smarter systems, skilled teams, and strategic alignment, companies can build supply networks that aren’t just efficient but also resilient, sustainable, and ready for whatever comes next.

Want to keep exploring? Check out the 5 Best Procure-to-Pay Software Solutions to Streamline Procurement.

Preview AI Intake for Orders

Take the product tour to see how the new intake experience works.